Now featuring ALLClear™ Technology Just Load and GO!

ALLClear™ Technology is designed to ensure optimal package and instrument conditions for sterilization, as well as:

- Instrument Warming

- Moisture Detection & Correction of Load

- System Diagnostic Check Prior to Sterilizaton Cycle

CONNECT. CORRELATE. COMMUNICATE

ASP ACCESS™ is ASP’s smart information-sharing technology providing data collection and communication of results across ASP sterilizers and hospital networks connected to ASP ACCESS™ Technology. Learn more about ASP ACCESS™

COMPLIANCE IS CRUCIAL

Simple, easy-to-use system that reduces operator error

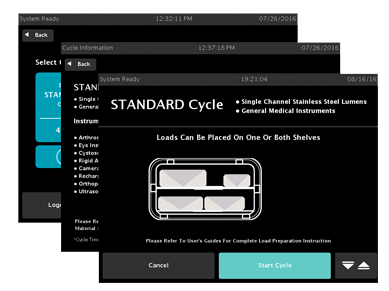

Graphic display indicating proper load placement for the selected cycle

Cycle information screens detailing the types of devices that can be processed in each cycle

Intuitive, on-screen instructions simplify system operation and staff training

FLEXIBLE & UPGRADEABLE

The STERRAD® 100NX System with ALLCear™ Technology is a low temperature sterilizer that offers:

- 4 cycles for sterilization of medical devices, including single channel flexible scopes

- Upgradeable technology as innovations come available

- Networking capability with multiple instrument tracking systems and hospital servers.

- Endorsements by the manufacturer for over 23,000 devices. Check your devices on our STERRAD® Sterility Guide here.

Designed for Safety by a Trusted Partner

Safety is a primary concern of ASP. There are over 15 million cycles successfully completed worldwide in 20,000 STERRAD® System. These cycles use a combination of hydrogen peroxide and plasma to rapidly sterilize medical instrumentation without leaving toxic residues and have been proven in a recent study to significantly reduce worker exposure to hydrogen peroxide emissions. Click here to learn more.

The system also includes:

- Touch free sterilant cassette removal

- Quality control integration

- Hydrogen peroxide monitor

Terminal Sterilization

Terminal Sterilization